Basic Electrical Safety

Risk of Arc Flash

Whether or not an arc occurs through air is a simple function of distance and voltage. The hazards associated with an arc flash are not however, a simple function of the fact that an arc occurs. The safety concerns associated with arc flash result from the energy released by an arc. When there is significant energy in an arc, the arc will produce a shock wave of both powerful percussion and intense heat. The effects of these factors on a technician working on an electrical panel that experiences arc flash can be devastating. The heat wave can be in excess of 2000°c and the shock wave can blow him back off his feet. Increasing numbers of arc flash incidents have been documented and the 2002 edition of the NEC requires all panels with potential arc flash hazards to be labeled accordingly. When a technician works on an electrical panel live that has a potential arc flash hazard, NFPA 70E requires he be provided with a flash suit to protect him against this hazard. This is an emerging requirement that will significantly impact the practice of electrical maintenance of industrial electrical panels.

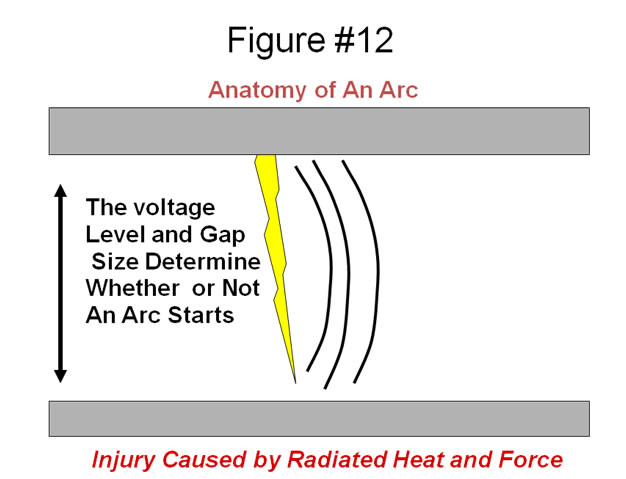

The challenge of providing adequate arc flash protection is to know which electrical panels present an arc flash hazard and therefore will require technicians to wear “flash suits” when they work on them. A common misconception is that arc flash hazards are only present on electrical panels with voltages in excess of 480V or 600V. This is simply not true. Arc flash hazards are a function of the energy in the arc. Figure #12 shows the anatomy of an arc.

The size of the air gap and the magnitude of the voltage determine if the arc gets started, but the energy in the arc is a function of the voltage causing the arc and the current in the arc. The current in the arc is not what is limited by up stream overcurrent protection, because most circuit breakers take a number of cycles before they trip. It is a function of the maximum momentary fault current that is capable of being supplied by the facilities power grid. While voltage varies from 120V to 480V, the energy in the arc will increase by a factor of 4, current may vary for 100A to 20,000A or more, which in turn increases the energy in the arc by a factor of 200. Therefore, the current available to an arc is the single most important determinant of an arc flash hazard.

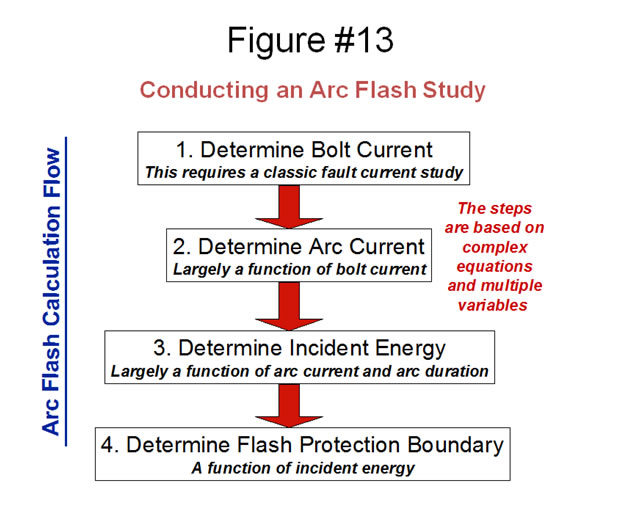

Figure #13 shows the essential steps in determining if an arc flash hazard is present.

While each of these steps requires a set of complex engineering calculations, a brief overview will help one better understand the process. An arc flash study necessarily looks at an electrical panel as it is installed in a given facility. Therefore, it makes no sense to attempt to do any arc flash calculations on an uninstalled piece of equipment, because the outcome of such a study will not only be greatly impacted by the facility that equipment is installed in, but also by where it is installed in that particular facility. The first step in conducting an arc flash study is determining bolt current. This is largely accomplished by conducting a classic short circuit study. The arc current is next calculated, and this is directly a function of the bolt current. The incident energy is next calculated as a function of the arc current and the arc duration. The incident energy then is used to determine the flash protection boundary or the area over which hazardous heat and force will be propagated as a result of the arc. This in turn will determine whether or not a flash protection suit is needed for a technician working on this electrical panel in accordance with NFPA 70E.